Flooding was yesterday – today it’s MQL!

“A lot helps a lot!” They say. This statement may be true in some areas, but it is usually out of place in modern metalworking. The future of cooling lubrication technology can be described more like this: “less is more!” The aim of this innovative technology is to increase savings and productivity with the precise and economical use of highly efficient cooling lubricants. Compared to MQL Technology, traditional “flood lubrication” or “surge cooling” is a highly inefficient, wasteful and costly practice. The savings potential of MQL technology compared to conventional cooling-lubrication technology is particularly evident in frequently used machine tools.

The advantages of minimal lubrication technology:

- higher profitability

- reduction of the amount of cooling lubricant required

- increased productivity

- clean, dry workpieces and workplaces

- reduced risk of workplace accidents

- environmental protection

- increased lifespan of your expensive machinery

- no disposal of old media

- current machines can be easily retrofitted

Save Money with MQL

In addition to increased safety for your workers and the environment, MQL Technology offers impressive cost reduction for your business.

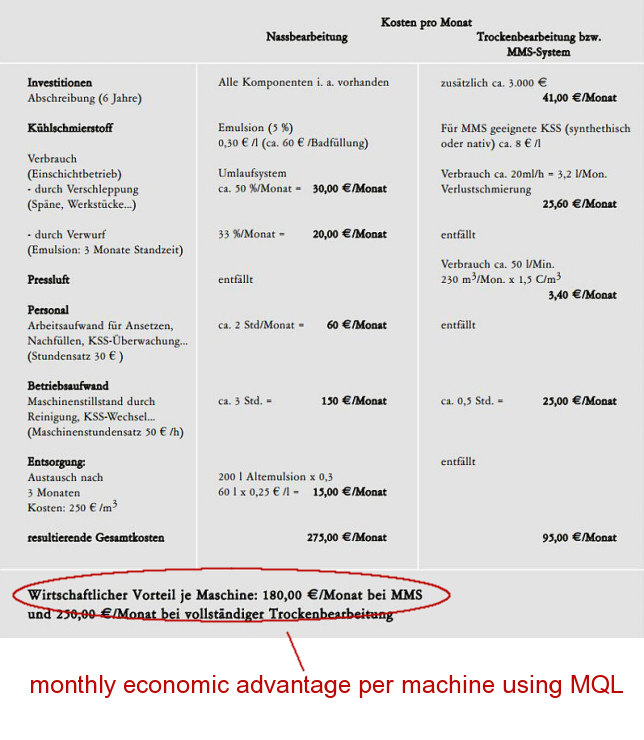

One example is shown below in the summary of a 2004 study by German ABAGitm, Pforzheim [www.abag-itm.de], which compared the cost of conventional wet processing to MQL for an individual single-shift machine. MQL Technology produced an average savings of approximately $200 per month.

Of course, the above calculation can only be a rough guide, since too many factors are included in the operating cost calculation of a machine tool. However, the high savings potential of MQL-technology is impressive. There are also positive synergy effects that are more difficult to name in Heller and Pfennig, e.g. the lower environmental and employee pollution, due to the gentler and resource-saving process of minimal quantity lubrication.

Reduction of cooling lubricant required

The name says it all: less coolant is required for a machine tool equipped with MQL. Although our lubricants are more expensive than those used for flood lubrication, much less product is required. As a result, using MQL Technology results in a direct cost savings of approximately 50%. Further savings are realized by drastic reductions in disposal and cleaning costs. Furthermore, disposal costs and the cleaning of machines and workpieces are practically completely eliminated.

MQL-technology increases productivity

When using MQL-technology, work steps such as disposal of old media and cleaning of tools and workpieces are almost completely eliminated. In addition, our lubricants are produced without additives such as preservatives and fungicides, allowing you to provide a healthier workplace, and protect the environment.