Description

The SA pump is a motor-driven pump for machine tools. It is suitable for smaller, primarily semi-automatic and manual band saws as well as for circular saws and drilling machines, where no large quantities of coolant are required (see pumps PA-35 and PA-70). They are designed for industrial use and are characterized by their robustness and long service life. The SA type coolant pumps have the advantage that they can be operated on both single and three pasess without changes, as they are driven by a single-phase electric motor.

The SA pump is a motor-driven pump for machine tools. It is suitable for smaller, primarily semi-automatic and manual band saws as well as for circular saws and drilling machines, where no large quantities of coolant are required (see pumps PA-35 and PA-70). They are designed for industrial use and are characterized by their robustness and long service life. The SA type coolant pumps have the advantage that they can be operated on both single and three pasess without changes, as they are driven by a single-phase electric motor.

The SA is designed for industrial use and is characterized by its robustness and long service life and meets the requirements of IP 54 (learn how IP-codes correspond with NEMA).

The housing is made of extruded aluminum or non-flammable, acid-resistant plastic in accordance with the following standards: VDE 0730 and UL 94. The pump shaft is made of V-2A steel, the bearings are from NSK, extremely durable and vibration-damped, mounted in semi-rigid shells, which leads to an almost vibration-free operation.

The pump is resistant to liquids permeated with particles (e.g. contaminated coolant) and all chemical compounds that are typically used in cooling lubricants. It can be throttled up to 80%, which enables optimal adjustment of the flow rate. The inlet port of the pump is compatible with Quick-Fit couplings.

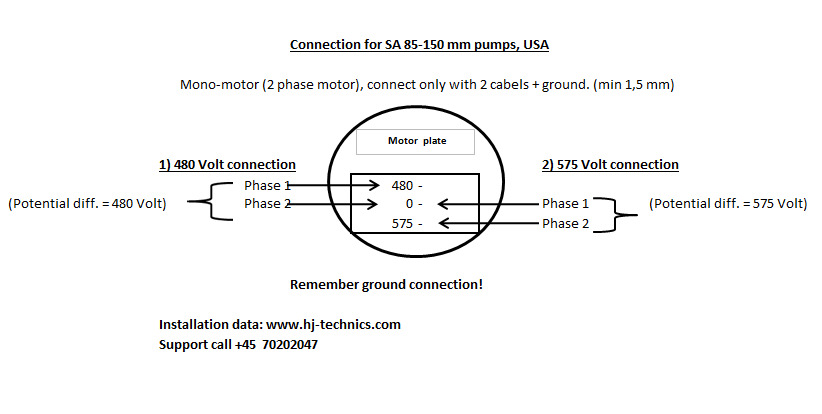

We can customize the SA for all mains voltages upon customer request.

Specifications

Power Consumption: 0.08 HP (60 Watt)

Voltages: 220-240 VAC, 2Ph | 380 – 400 VAC, 2 PH

Phases: 2 Phases

Frequency: 60 Hz

Discharge Head: 14.1 feet

Capacity: 3.7 GPM (14 l/Min)

Immersion Depths: 3.3 in (85 mm) – 5.9 in (150 mm)

Cover Material: Extruded aluminium, POM

Impeller Material: POM

Shaft Material: stainless steel (AISI 303)

Bearings: CW long-life bearings in semi-rigid supports

Weight: 2.3 lb

Outlet Thread Ø: 3/8 ”

Protection Category: NEMA 3 (IP 54)

SKU: 6110

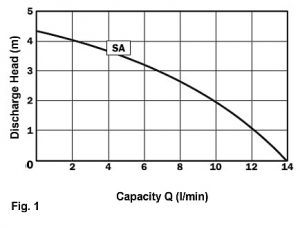

Discharge Head & Capacity

Figure 1 shows the maximum delivery rate depending on the discharge head for the pump SA.

Figure 1 shows the maximum delivery rate depending on the discharge head for the pump SA.

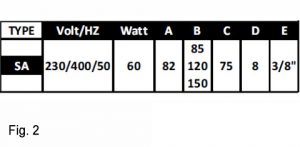

Figure 2 shows the length of the immersion tube under “B”, which must be taken into account when ordering, see also Figure 3.

Figure 2 shows the length of the immersion tube under “B”, which must be taken into account when ordering, see also Figure 3.

Installation

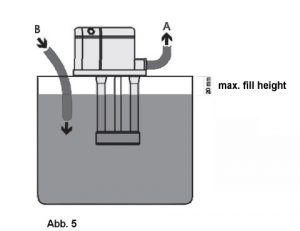

The pump is to be installed on the tank as shown in Figure 5 so that the immersion tube is immersed in the coolant. The housing part that contains the electric motor must not come into contact with the coolant. Ensure that there is adequate overflow in the tank.

The pump is to be installed on the tank as shown in Figure 5 so that the immersion tube is immersed in the coolant. The housing part that contains the electric motor must not come into contact with the coolant. Ensure that there is adequate overflow in the tank.